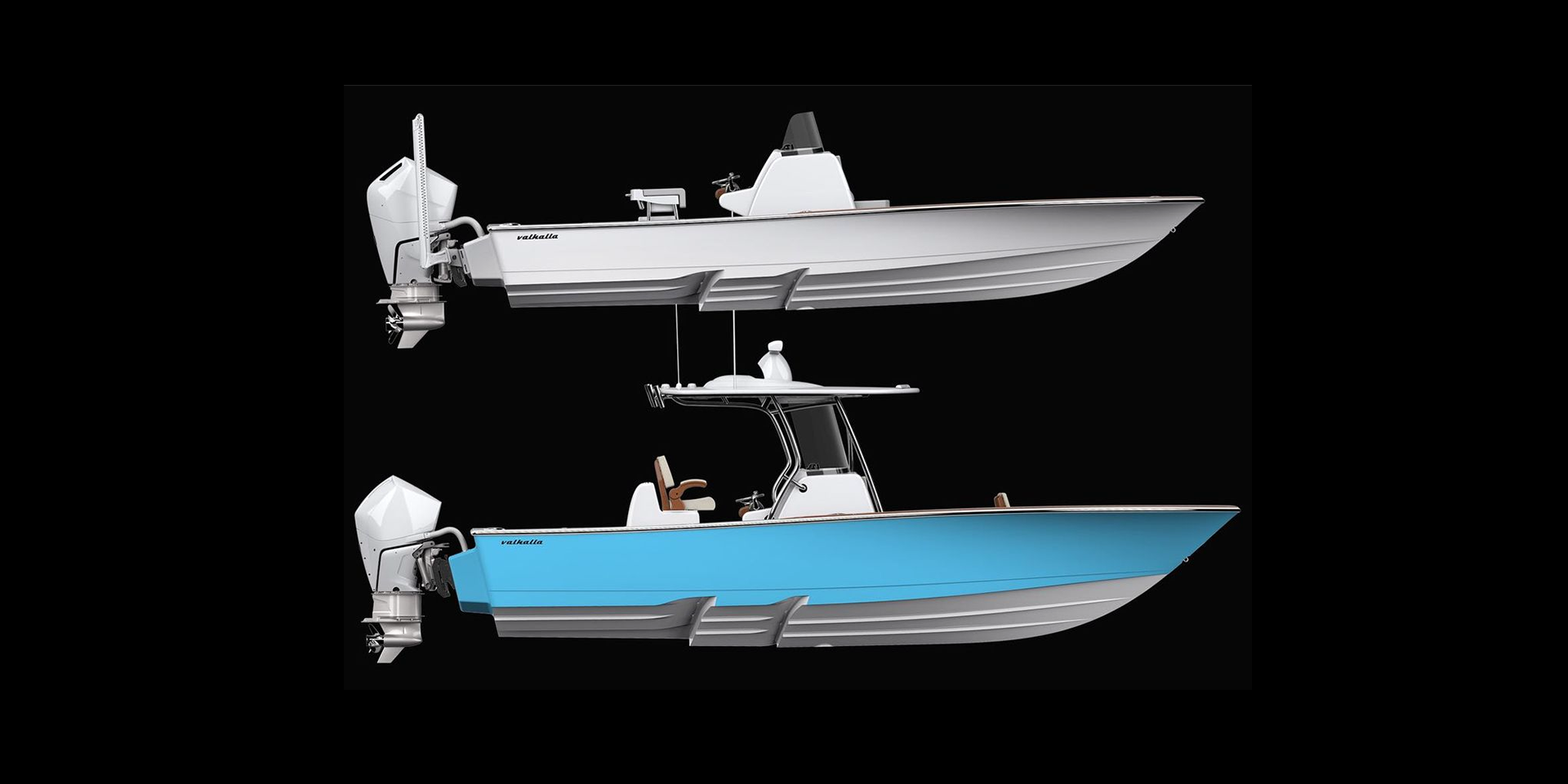

Valhalla Boatworks shines the spotlight on the V-33

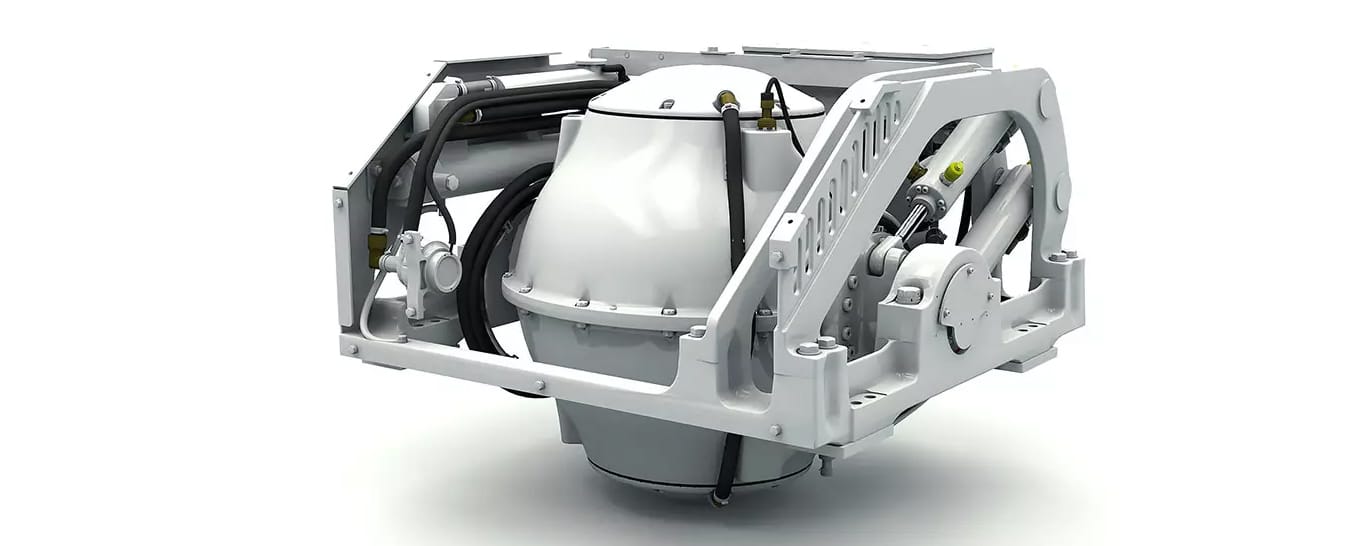

Brothers Bill and Bob Healey founded Viking in 1964 with a commitment “to build a better boat every day.” It’s a philosophy they still use, along with their sister company Valhalla Boatworks, six decades later. This philosophy is one that shapes the Valhalla V-33. The building process for this model includes many details. Valhalla’s dedicated team of laminators work in the Fiberglass Department to set the hull molds for each V Series model with a dedicated hydraulic turning system. This helps to increase build efficiencies.

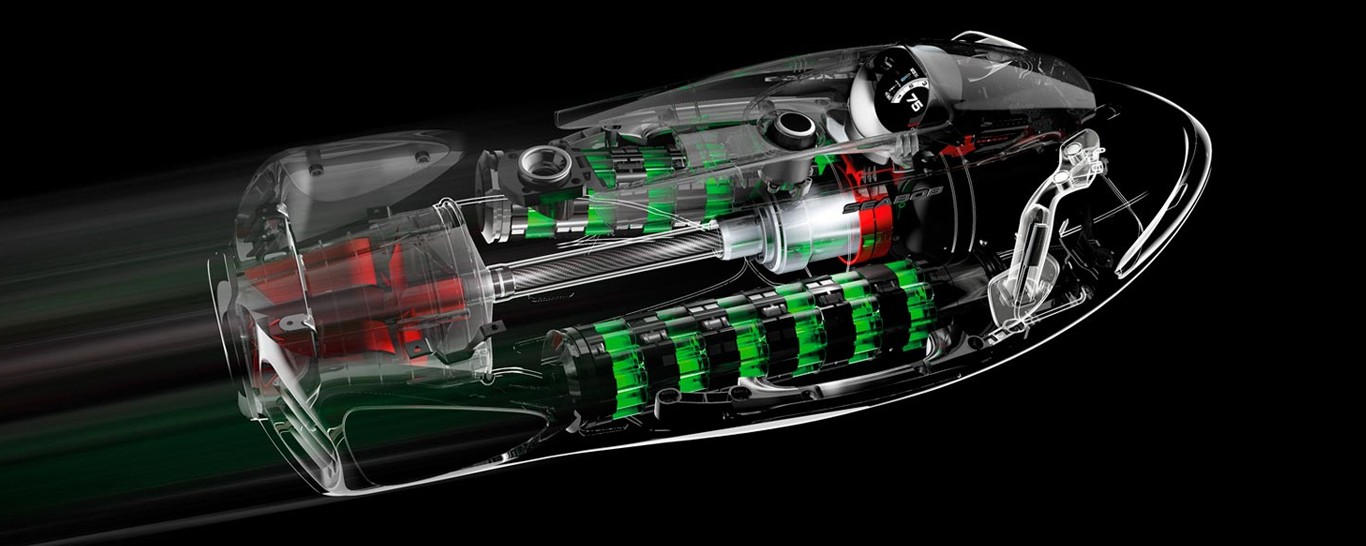

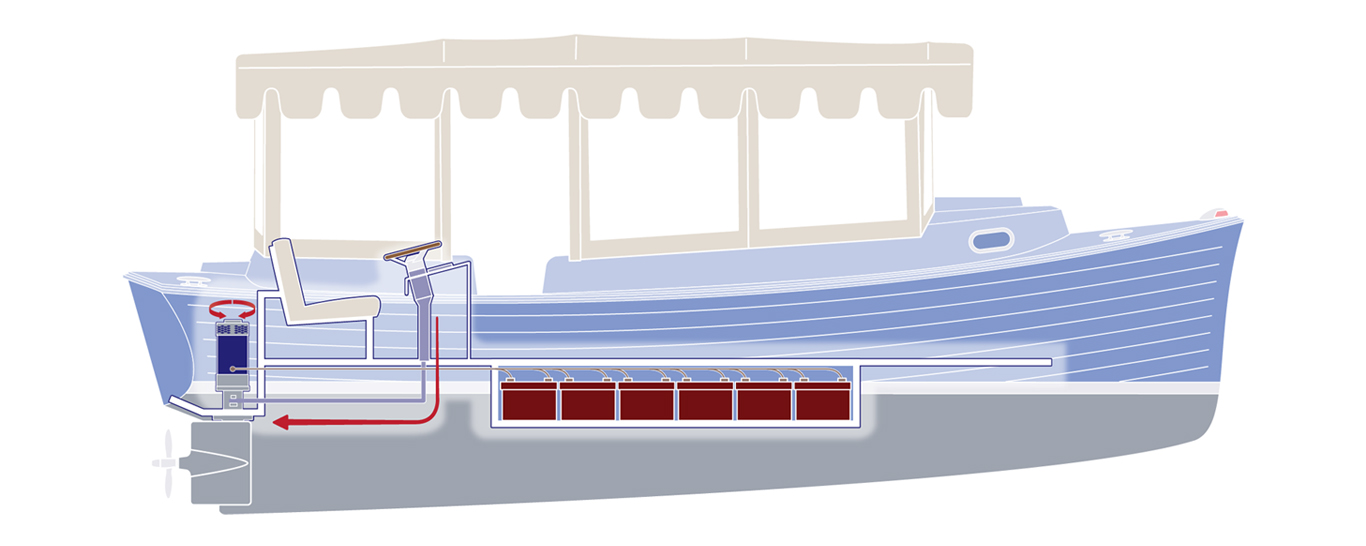

Another important detail in building the V-33 is the fish boxes. In order to set the port fish box in the hull of the V-33, the Department Leadsmen will drill temporary aluminum flanges to the stringer grid to secure the box. This step is followed by injecting foam under and around the box, which holds the structure in place while providing insulation. The large beams running athwartships are also utilized to secure the box during foam injection.

In the Fiberglass Department’s small parts area, builders use a series of clamps to fabricate the dive door lift gates. The clamps hold a special phenolic material – sandwiched between fiberglass laminates – that serve as a backing for mechanical fasteners used to install the rubrail. Other parts built here in small parts include dive doors, live wells, fish boxes and glove boxes.