UK manufacturer Williams Jet Tenders leads the waves with the launch of its 10,000th tender.

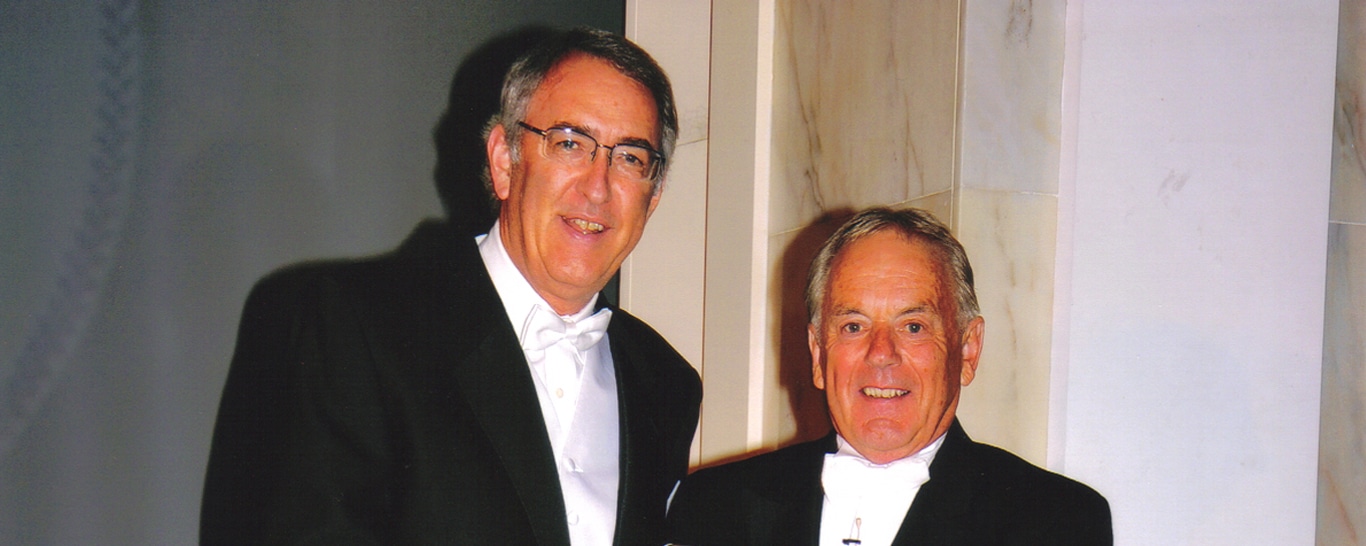

Williams Jet Tenders is the world’s leading jet tender specialist hits a milestone this week – Williams launches 10,000th tender. Williams Jet Tenders is a British success story that began, as all good stories do, in a shed. Two brothers turned their passion for the sea into a thriving business. They accomplished this with craft, dedication, and innovation at its core.

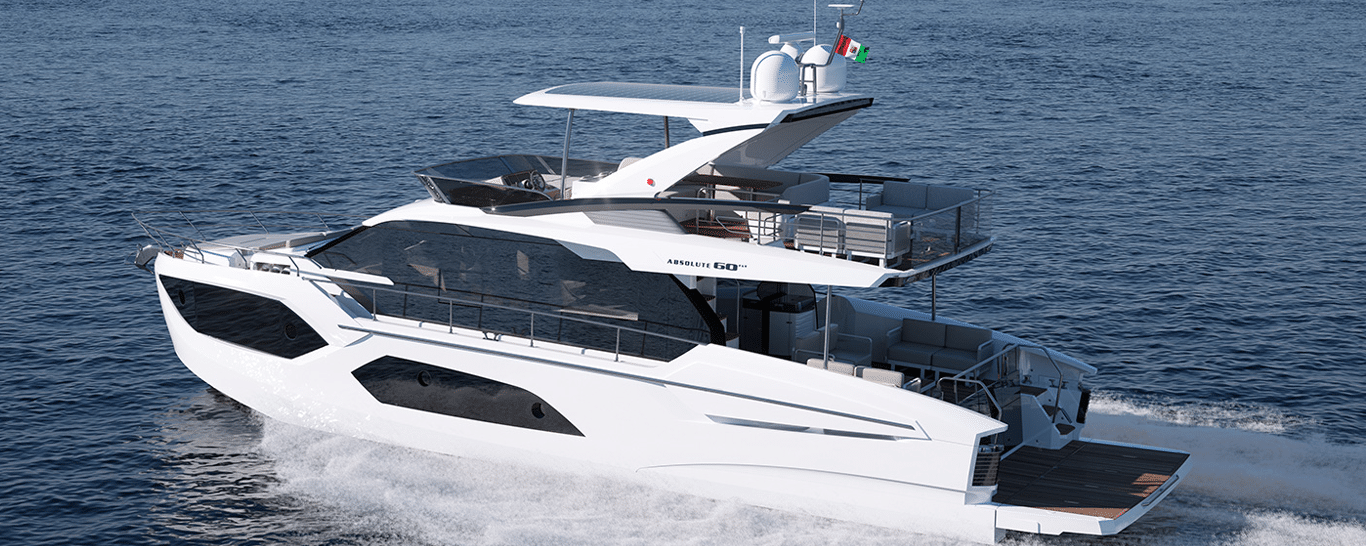

Williams has revolutionized the tender industry. Their boats are a perfect blend of power, luxury, and practicality. The company now employs over 100 staff and this year, launch their 10,000th tender.

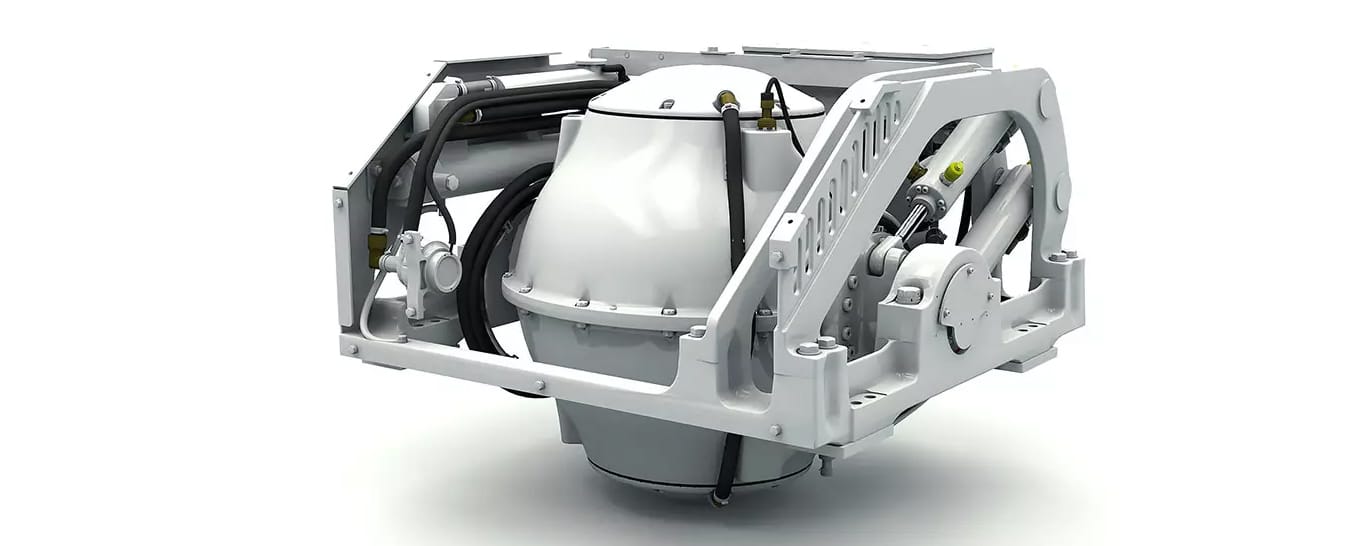

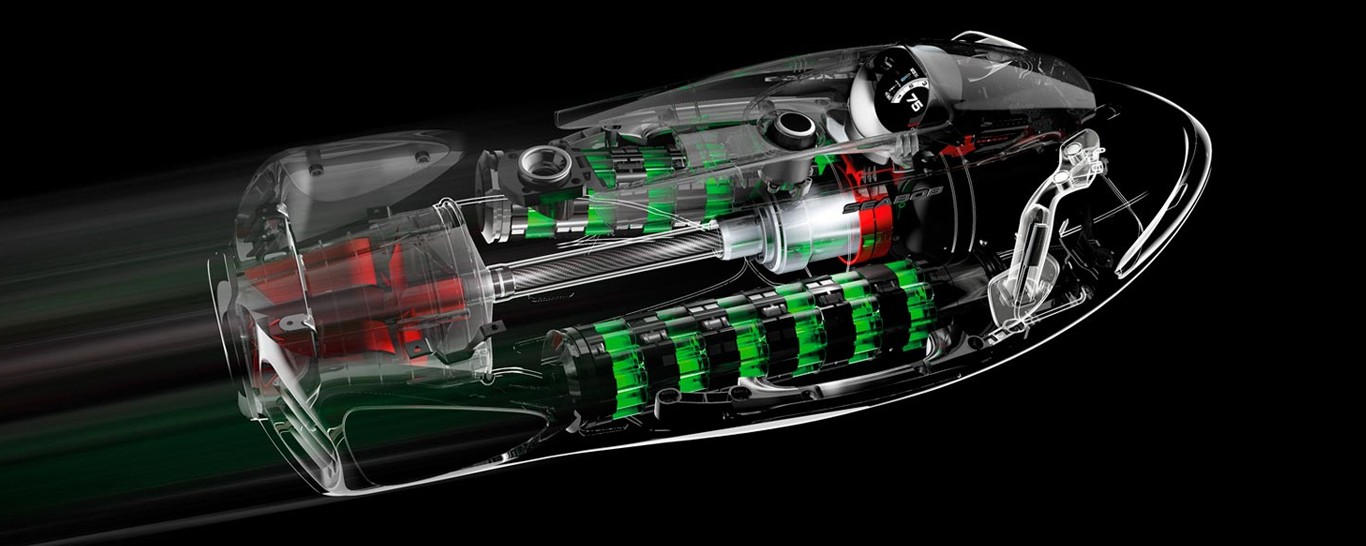

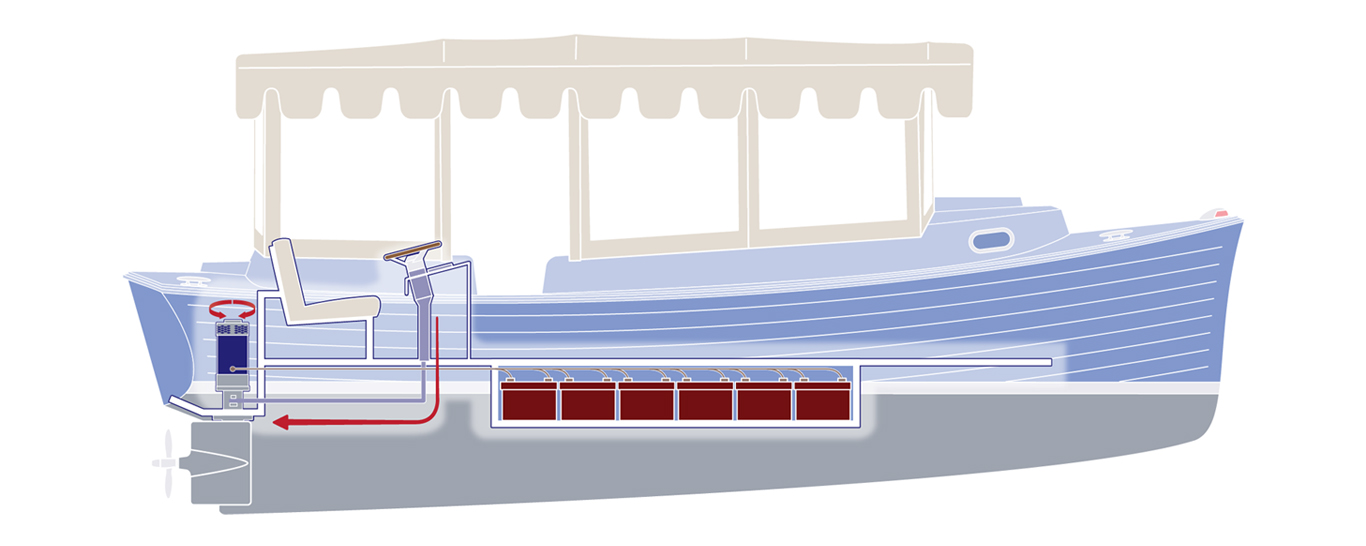

Williams’ first boats were a far cry from the luxury tenders built today. This all started with wooden dayboats designed to cruise the French Riviera. It shifted up a gear in 2002 with the release of the Ski Rib. Ski Rib was a fast, agile yacht tender designed to fit onboard 40-50ft motor yachts. It was an instant success. This led to the development of a ground-breaking generation of jet tenders. The Hornsby brothers helmed projects along with their visionary business partner, Roy Parker.

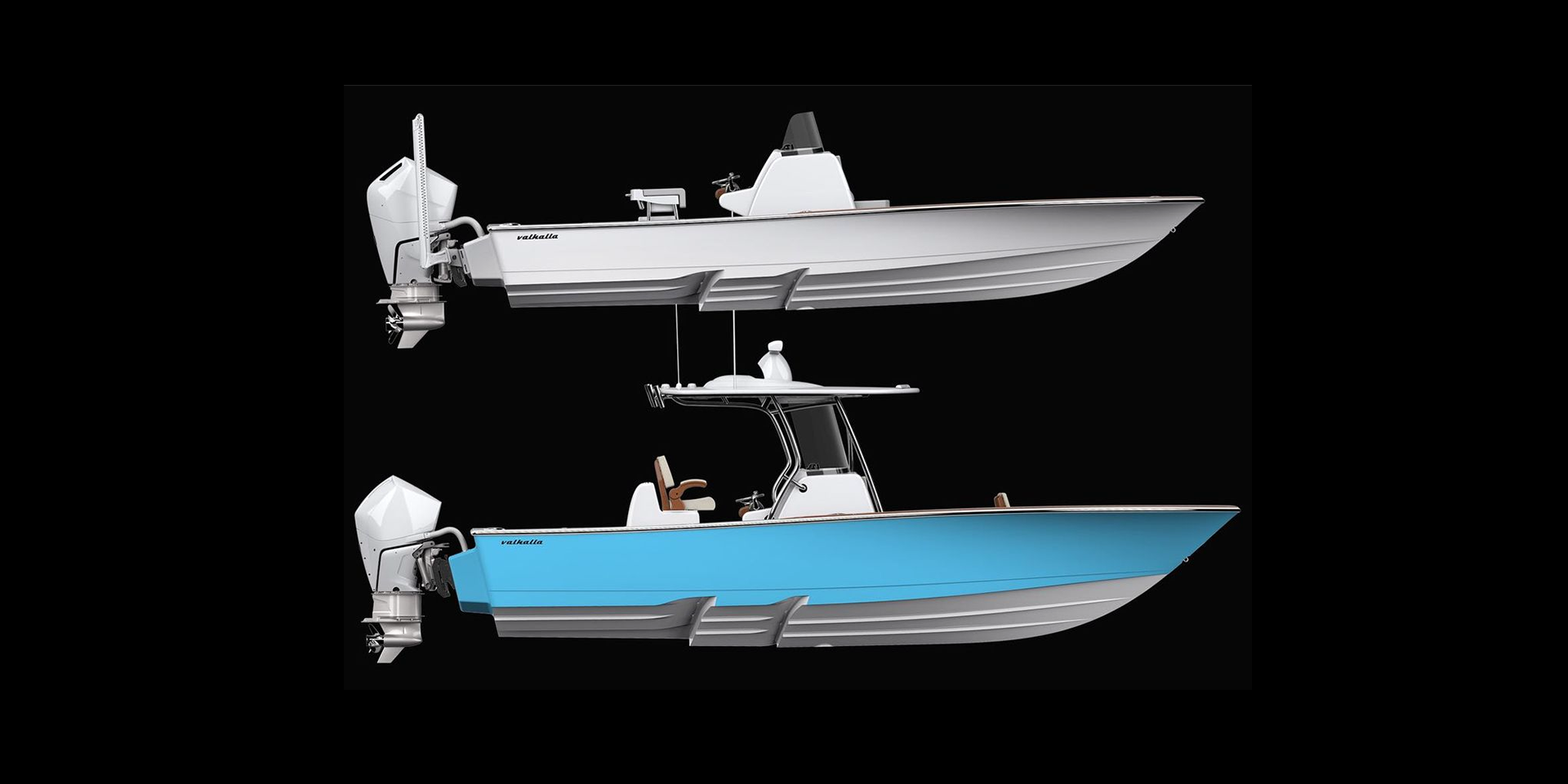

Over the years, Williams has expanded to meet demands of the most famous boating brands. Today, Williams produces 14 different models across five ranges. The five distinct model ranges include: TurboJet, DieselJet, SportJet, EvoJet and MiniJet. The company builds over 950 boats per year.

“To launch our 10,000th tender is a momentous occasion for everyone involved with the brand. We’re proud of what we’ve achieved, and it’s all down to our amazing colleagues and customers but trust me when I say this is only just the beginning!”

Mathew Hornsby, Sales Director at Williams Jet Tenders

The building of the 10,000th tender doesn’t mean Williams Jet Tenders will rest on its laurels. The company recently announced an investment in a new in-house moulding facility. Included is a dedicated large-scale boat production facility at its Oxfordshire headquarters. This will allow the team to build larger models. They will also be able to control every element of the manufacturing process. This stems from quality assurance to helping reduce emissions and waste.

This is one of many big changes the company has made during the last 12 months.